Visual UI

complete system information status display and related settings management can also cooperate with the development of dedicated billboard screens.

Predictive maintenance

Through the analysis of each component’s action records, it can detect abnormalities or component damage in advance to reduce the sudden abnormal production line stopped.

Device abnormal message collection

records the operation or abnormal information of each device in detail, and provides client’s system to analyze and understand the cause to avoid the abnormalities.

Automatic changeover

Through unified management formulated the production to meet the changeover requirements quickly and accurately.

Predictive maintenance

When the overall yield of the production line is too low, the person will be notified to deal immediately to reduce the follow-up rework or scrap.

Traceability

Complete station information reporting, creating the product traceability.

MO LineCheck

Product input and output barcode card control to prevent the mis-line or wrong order.

Through the analysis of each component’s action records, it can detect abnormalities or component damage in advance to reduce the sudden abnormal production line stopped

records the operation or abnormal information of each device in detail, and provides client’s system to analyze and understand the cause to avoid the abnormalities.

Through unified management formulated the production to meet the changeover requirements quickly and accurately.

When the overall yield of the production line is too low, the person will be notified to deal immediately to reduce the follow-up rework or scrap.

Complete station information reporting, creating the product traceability.

Product input and output barcode card control to prevent the mis-line or wrong order.

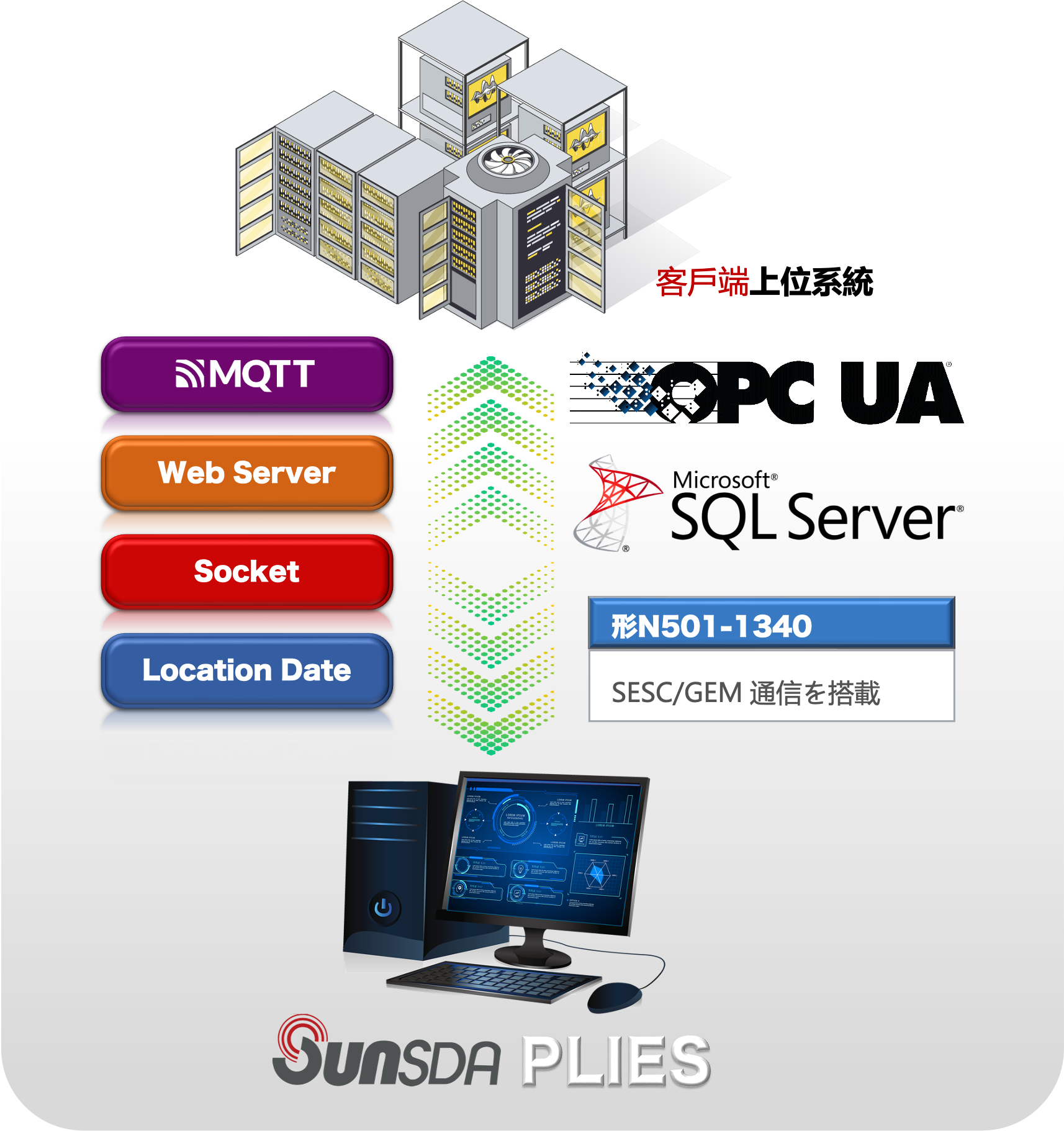

架構 說明

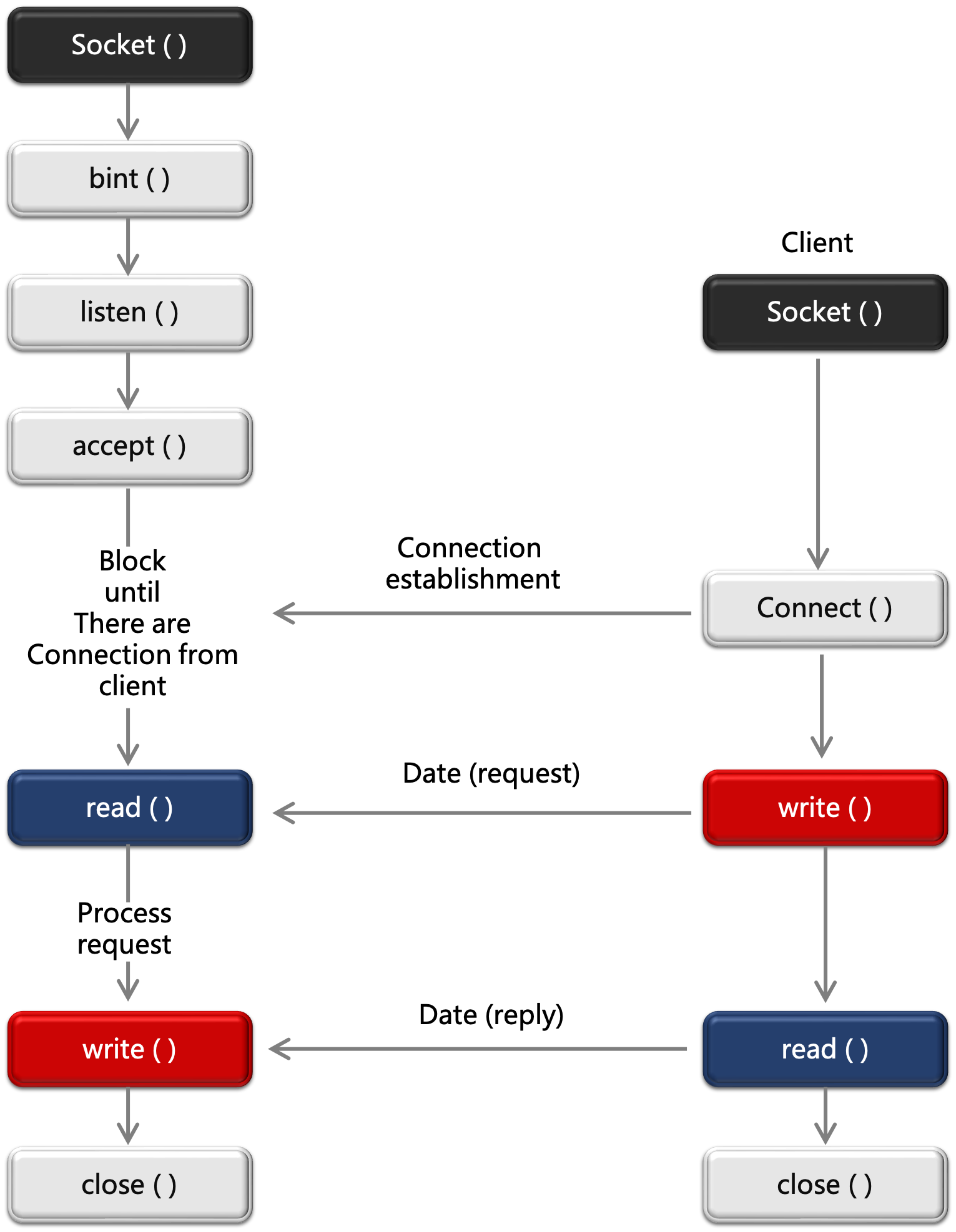

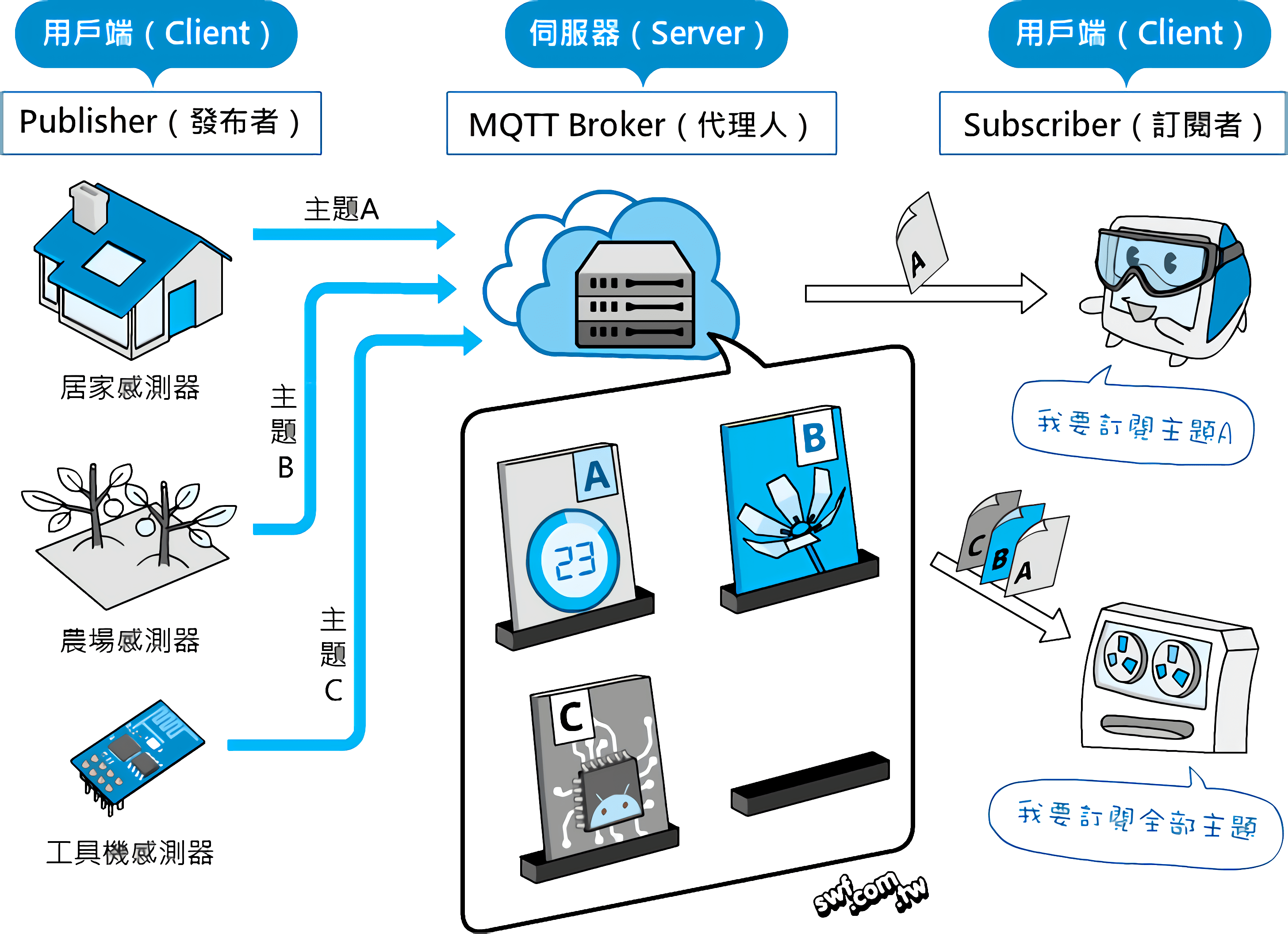

- According to the client’s current MES, Shop Floor and other system, customized the related docking character strings or other data formats carry out handshake or using a market-sharing protocol handshaking.

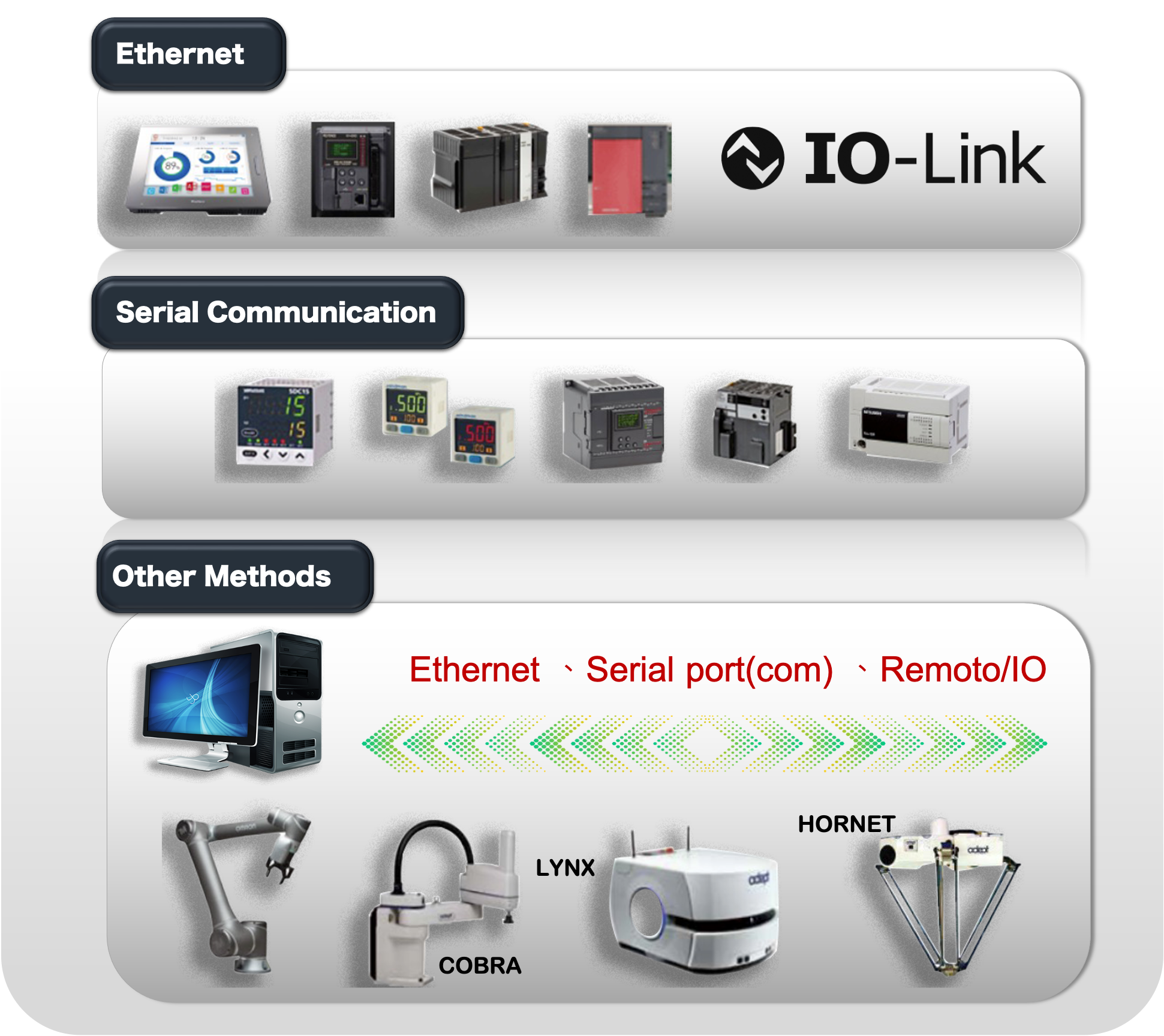

- Collecting the relevant important information accords to the client’s current equipment, form, robot, etc.

Communication Architecture

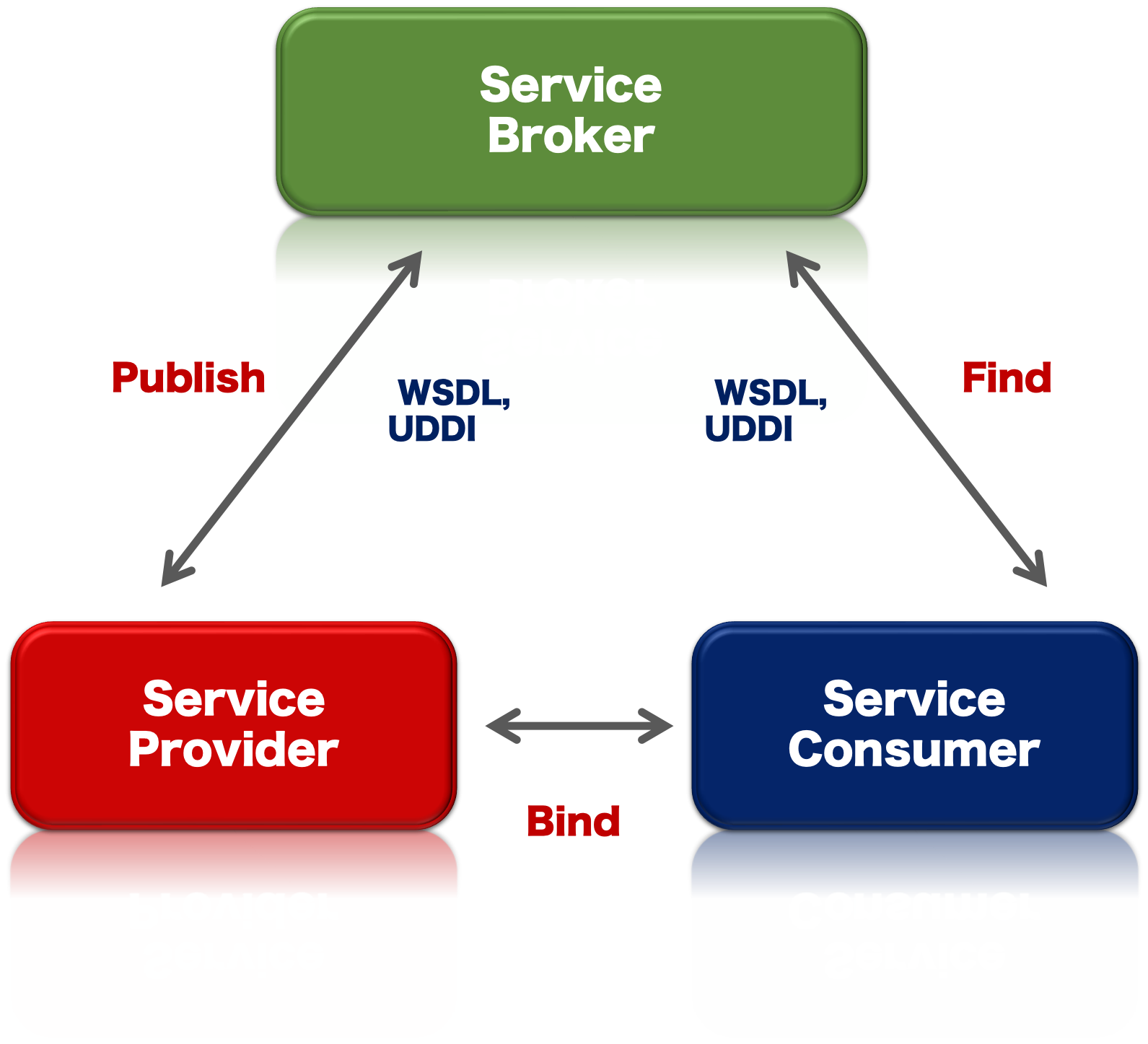

• WebServices Architecture

Operation Flow:

- Server provider provides to develop Web Services。

- The service provider deploys Web service to the server environment and logs the relative information into UDDI registry database with the service broker.

- The consumers of the service go to UDDI registry database to find the request service

- The consumers of the service can use the service after they obtain information about the web service